Watch Cleaning Machine Ultrasonic & Vacuum Elma Solvex VA - HCVA

Brand: Elma

Elma's Primary UK Distributor

Elmasolvex VA Watch Cleaning Machine for manufacturers and service centres who require ultrasonic cleaning.

Elmasolvex VA uses multi-frequency ultrasound for regular component cleaning as well as a separate frequency for very delicate parts that require special handling.

The parts are cleaned in a chamber in which cleaning and rinsing solutions are changed automatically. Programs are configured and launched quickly and easily using a high-resolution colour display. The system provides reliable default programs and an expert mode that allows watchmakers to configure and save their own tried and tested parameters.

A special feature is the fact that the cleaning cycle, all rinse programs and the drying cycle are carried out in vacuum. The chamber is in vacuum during all the process steps to remove even the smallest gas bubbles from the parts, cavities and even the mesh in the cleaning baskets. This ensures that cleaning and rinsing solutions reach every part of the item being cleaned. In addition, multi-frequency ultrasound is available for every step, including rinsing (1x cleaning, 3x rinsing).

The last step is drying this step is also completed in vacuum, the boiling point of the rinsing solution is reduced and the items are gently dried at a lower temperature.

Ultrasound and vacuum are a perfect technical combination not just for cleaning, but also with regards to maximum explosion protection. Ultrasound is technically regarded as a form of heating and is required to undergo extensive monitoring and safeguarding procedures in line with the latest state of technology. An open monitored system without special nitrogen flooding is conceivable, but too extravagant. There is a technical solution: using a vacuum takes the explosive atmosphere out of the system. Integrated technical safety controls ensured that the machine received external certification (by TÜV Rheinland).

However, safety does not stop with explosion protection, the operator must be considered, too. Even very fine solvent fumes that exit the machine and might no longer be potentially explosive can pose a risk to operators if they breathe in the fumes over an extended period.

Elma offers an extraction solution for all machines. It can be connected to any inhouse extraction system. If no internal extraction system is available, all three machines can be equipped with optional filters which allow the machines to run independently.

Certified explosion protection and staff safety in conjunction with optimised vacuum ultrasonic cleaning are a great help when it comes to the manufacturing and servicing of increasingly valuable watch movements.

Dimensions Ø600mm x 610mm (Height)

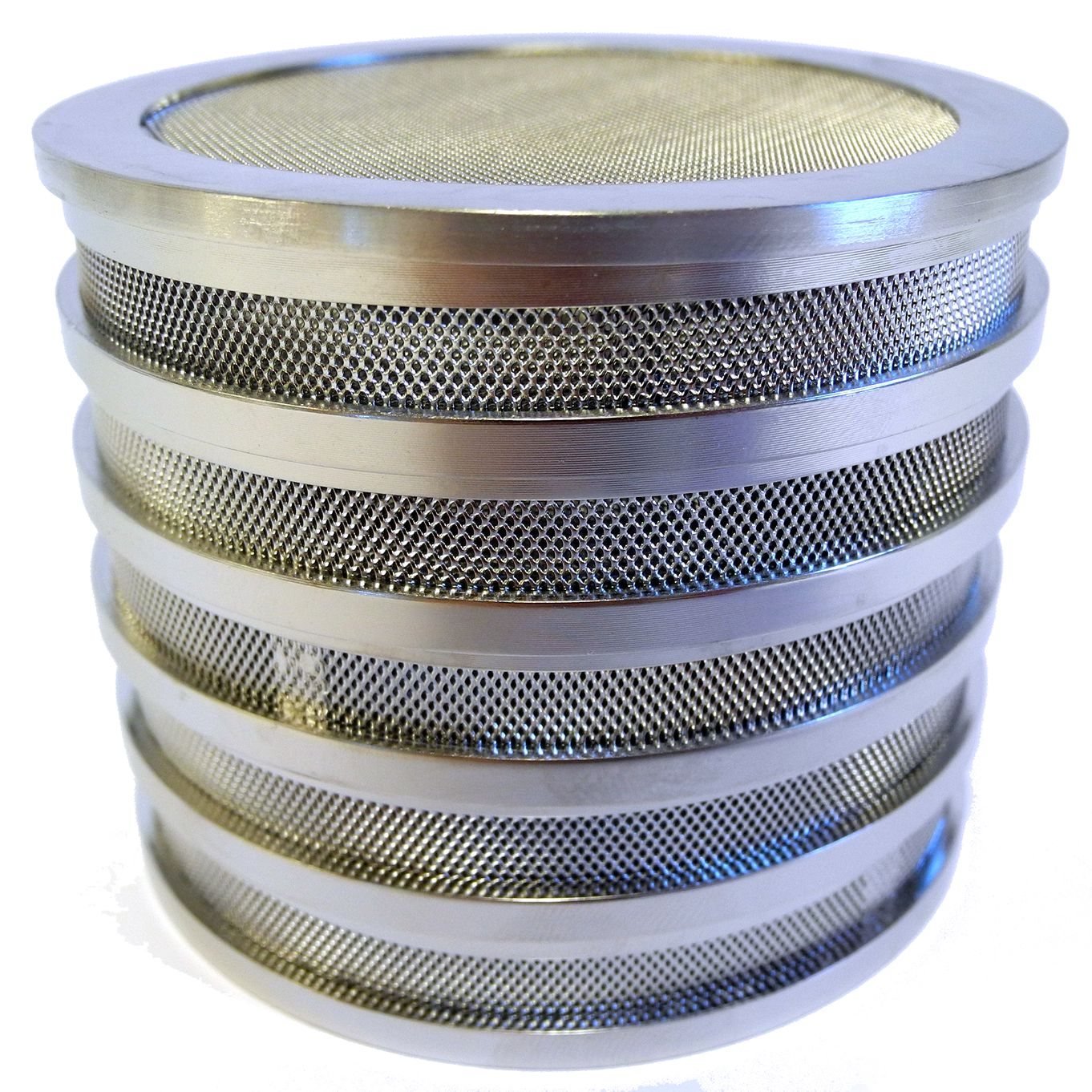

Supplied With

- 1 x Ø80mm Basket Frame

- 4 x Liquid Containers (HCVA29)

Optional Extras

- Ø80mm Basket Set Complete (HCVA01)

- Ø64mm Basket Adapter (HC5112)

- Watch Movement Holder For 12 Movements (HCVA07)

- Pager (HCVA28)

- Carbon Filtering System (HCVA04)

We Can Also Undertake In-House At Our Biggin Hill Head Office The 5 Year Service On The Elmasolvex VA please contact [email protected] For More Details.